There is no universal safety solution

It’s all about communication, cooperation, control and competence

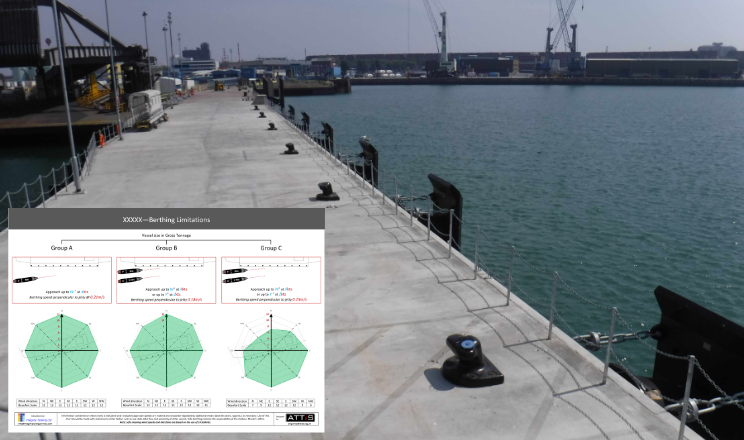

Each location where a task is carried out generates its own unique concerns regarding safety. There are always the relevant concerns of the task itself but the location, as well as the individuals both carrying out the task and in the vicinity, are also of interest. An office setting may appear at first to be quite benign, but what if the office is on the 20th floor, or has a high number of public visitors? Installing an electric socket may be the work of a moment for a trained electrician, but what if it’s 100m up in the nacelle of a wind turbine? Proper regard for safety must consider all these aspects – the environmental and social settings – if it is to truly effective.

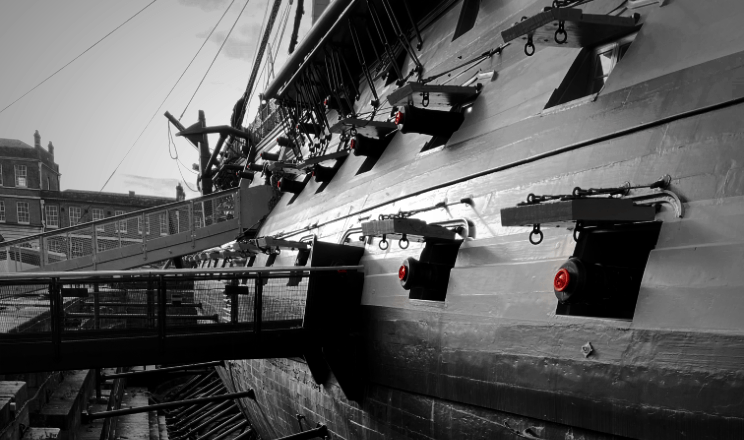

Repairing a wooden floor, in a shed or house, may be quite a simple task that requires only a few considerations of the tools used and PPE required. Turn the shed into a treehouse and you now have to consider fall prevention and issues with floor loading. Now put the repair on a historic vessel, one that in still in service with the Royal Navy (hard to believe but true). Surround yourself with very old and dry timber and allow the general public to continue visiting the vessel. Then add the fact that the repair must be carried out sympathetically using the original methods of heating tar, mixing with hemp rope and jamming this in between the planks. Things have now started to get a little complicated.

It may not be the usual thing that safety practitioners get asked to advise on but it is the kind of thing that the experts at Attis get involved with, along with public infrastructure and many other highly visible and high-value projects. Having to create safe systems of work for one of the most famous warships in the world may be a great honour, but, as with all work at this level, it requires focus and a pragmatic approach. In essence, it requires the Four Cs approach of communication, cooperation, control and competence.

The competence of people like electricians, carpenters and boat builders is gained through qualification and experience. The reason we have these valued tradespeople is because of the skills and knowledge they bring to the workplace. Communicating with them about their methodology and work practices is vital in understanding how the work will be done. For a safety professional, it is not only important that they understand what the work will entail but how it will be achieved. Some work practices may seem at first to be eccentric or even unsafe, but this is why we have competence. Working on live electrics, for example, may be anathema to a safety practitioner but in certain circumstances it is unavoidable for the trained electrician.

Breaking down any work into its component parts is an excellent way to understand the relevant risks at each stage. This way, each stage and each risk can be assessed and the appropriate mitigation provided. Such mitigation might include specialist tools or removing a particular hazard or even relying on the individual’s competence. It sounds easy but it takes a skill and knowledge to identify relevant risks and cooperate with the workforce about the right sort of mitigation. In short, it takes competence on the part of the safety professional.

Once the work is planned, it needs the right controls to be in place to ensure it is carried out correctly. This falls under the framework of instruction, information, training and supervision. Once again, all of these need to be appropriate to the work, the location and the individuals involved; not only carrying out the work but also in the vicinity. It is rarely as easy as just writing a risk assessment and letting people get on with it. Controls also need to consider exceptional circumstances, such as fire, bad weather or sudden deviations in the work or the workplace. And communicating this to the right people is also crucial – having a terrific evacuation plan is no good if no one in the workplace knows what it is.

The proper implementation of safety isn’t necessarily easy, and is rarely something that can be done “by the numbers”. It’s about applying logical steps to the risk assessment process and forming a safe working procedure that people can effectively use to complement their skills and experience.