Why it is important to have an effective design strategy (part 4a)

Did we get what we asked for?

Once the validation design review is complete, and the stakeholders are agreed that the product can enter service, a formal acceptance should take place. This will be from the client to the controlling authority for the design at the point that production ceases. This may be the producer, the designer, the project manager or some other entity and will have been decided and documented as part of the management structure at the beginning of the project. This formal acceptance again demonstrates that all parties have concluded their responsibilities appropriately, as well as documenting that the client has accepted the final output of the project thereby releasing the producer from their involvement in the design process. Where the producer is contractually obliged to continue their involvement with the product whilst it is in use, perhaps for the purposes of setting-to-work, training or snagging, the formal acceptance also provides a reference point for the date from which this activity commences.

- The acceptance document package, passed to the client upon formal acceptance into service, might contain the following:

- The risk register, detailing risks mitigated, controlled and outstanding.

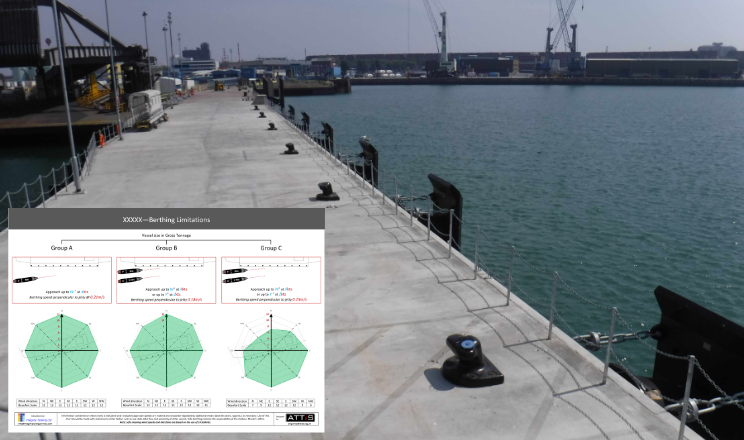

- Details of any limitations of operation.

- Details of any systems that are not in service, perhaps where the client is to integrate them at a later date (lighting or CCTV systems for example).

- Approval certificates for structures, materials or components.

- Test certificates.

- Maintenance requirements, procedures and periodicity and/or manufacturer’s guidance notes.

- Details of any hazardous materials, their location and any special precautions or handling techniques.

- Drawings, plans, schematics and general arrangements.

- Safety case(s).Limitations of operation.

The formal acceptance should also identify any training requirements for the use, maintenance and disposal of the product. This may be in the form perhaps of specialist training that is required to a manufacturer’s stipulation or a general or accredited level of qualification.