Why it is important to have an effective design strategy (part 3)

Is the design good enough to start construction?

The full/technical design review at the end of the design process is the last opportunity to ensure that it meets all the objectives of the client’s agreed requirements. It is also an opportunity to ensure the design meets the core constraints of the project: can it be made in time; will it be made to budget; and will it be to the expected quality? The capability and capacity of the production stage should also be judged against the requirements of the design, which should now be apparent.

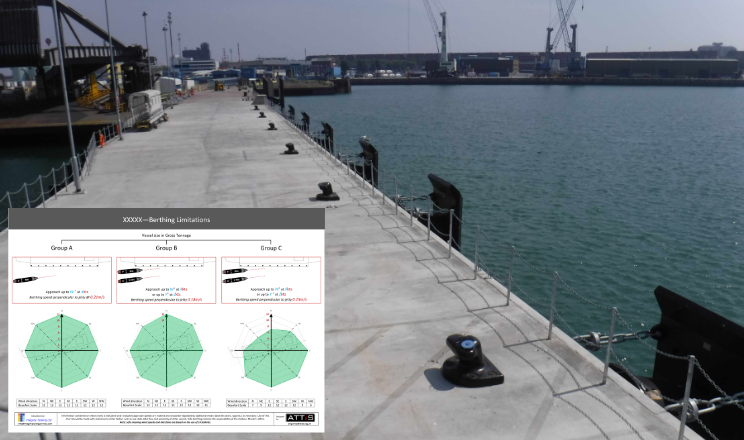

Supplementary to these considerations are whether observable and foreseeable risks have been identified and recorded, and that suitable mitigations or control measures have also been identified as well as naming champions to carry out these measures where possible. The design should be tested against the operational and maintenance requirements—the normal and abnormal states of operation—as well as any exceptional or emergency conditions that may be foreseeable.

The full design review is also where the validation plan can be examined for objectivity and completeness. All of the systems, materials or components of the design that require validation at the end of the production stage should be identified and the relevant and necessary procedures, certification or documentation that are required to substantiate the validation process listed against each one. The validation of specialist systems, materials or components would have been recorded after consultation with the relevant suppliers or manufacturers earlier as part of the additional stakeholder process.

The full/technical design review is an opportunity to ensure that:

- Key stakeholders are agreed that the design remains viable or whether it should be halted, revised or refined.

- The design has reached a suitable level of maturity to be produced.

- The design remains faithful to the client’s statement of requirements.

- Emerging risks connected to the production and operation of the product are identified and mitigated.

- The objectives of the validation plan have been agreed by key stakeholders and this is embedded into the production stage.

- Formal approval to move to the construction/production stage can be agreed.